Automation Gripper

EQUIPMENT | Italtronic

The client is a company specialized in the design and production of plastic enclosures for electronics, offering modular and customizable solutions for various applications.

The company approached us in the process of upgrading a new automated machining center.

Our goal in the project was to support the development of the new equipment by studying solutions to maximize production efficiency with a flexible system capable of handling different products without requiring frequent setup changes.

We analyzed the operation of the system and production requirements, designing solutions to reduce setup times and minimize machine downtime while ensuring maximum versatility.

With the identified solutions, it was possible to eliminate the centering station originally planned by the system manufacturer.

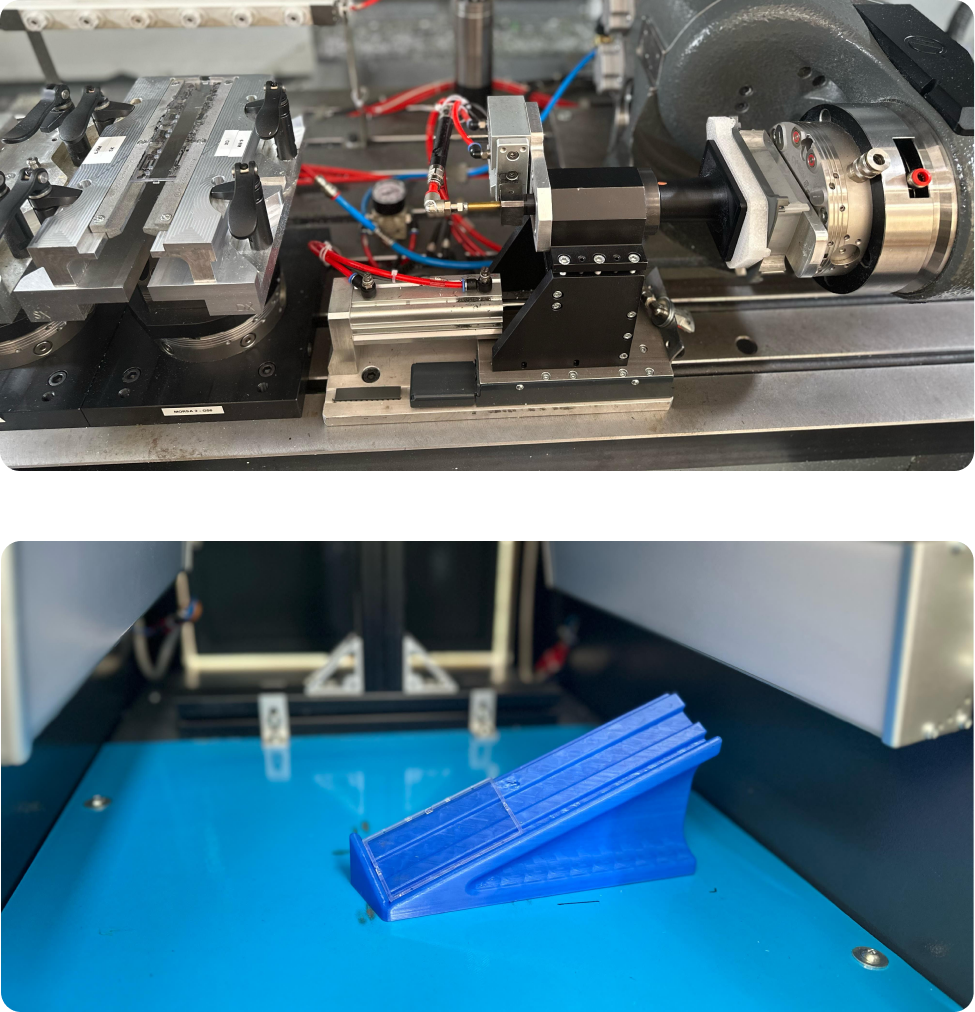

Thanks to 3D printing with Raise3D Pro3 and our expertise in Additive Manufacturing, we created prototypes to test and optimize the proposed solutions.

This approach improved precision and reliability, speeding up implementation and reducing the risk of errors.

The identified design solutions and the quality of the produced prototypes enabled the client to use the printed components directly in production without requiring mechanical processing, thereby also reducing setup costs.

The solution we developed is based on a modular approach: thanks to custom-designed equipment, the client can mount multiple products on the same system without having to reconfigure the equipment.

This has resulted in significant time and resource savings, as well as greater fluidity in daily operations.

Thanks to our support, the client has achieved the following key benefits:

Investment optimization – No unnecessary costs for equipment dedicated to individual products and reduced setup costs.

Reduced setup times – The system is faster and more productive, with no unnecessary interruptions.

Increased operational efficiency – With a single versatile piece of equipment, production management has become more agile and straightforward.

Greater flexibility – Use of 3D-printed setups, even with flexible materials (TPU), allowing for compensation of production tolerances.

Development of complex solutions – The use of 3D printing has enabled the implementation of more complex solutions that would otherwise have required higher investment costs for tooling.