Discover some of our best works

Are you curious and would you like to see some of our projects? Discover our best works, you'll find a wide selection that shows the REND method!

The utmost precision for a striking result

Our long experience in the industry allows us to deal with any kind of request, from the improvements of already existing systems to the development of innovative projects.

We take care of all the phases of the product development process. Starting from the feasibility analysis up to its realization, through the design and development of a prototype.

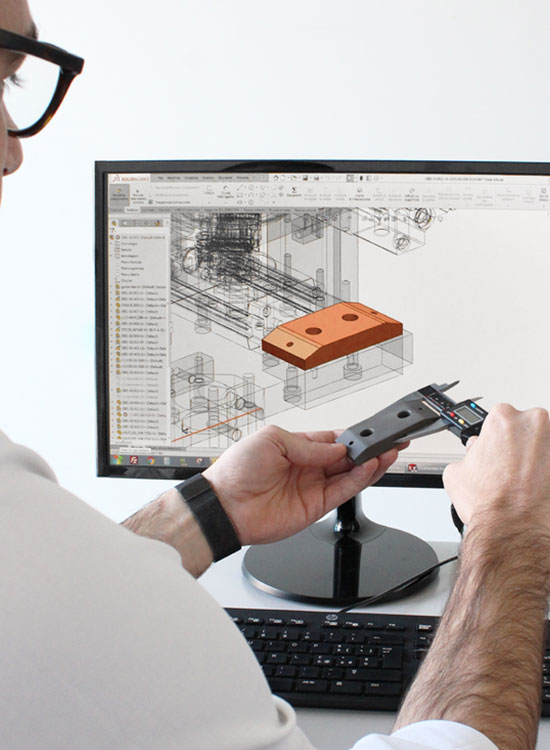

We have licenses for the most popular 3D and graphic CAD modelling software on the market: Solid Edge, AutoCAD, Autodesk Inventor, Solidworks, Siemens NX, Catia, Creo Parametric, Rhinoceros, Keyshot, Illustrator, Photoshop, Indesign.

Our long experience in the sector enables us to develop projects even when the request only comes from an idea or the desire to find a solution to certain problems. Starting with a blank canvas, we carry out market and feasibility analyses, laying the foundations to find a solution that can meet the client’s demands.

Before proceeding with the design phase, every idea, request and need is examined by our R&D department, which provides a thorough feasibility analysis. In this way, the practicality of the commissioned design can be understood in terms of costs, processes and main features, along with a prediction and analysis of the possible results.

Reverse engineering is particularly useful when mechanical parts, molds or entire systems need to be modified. We carry out surveys characterized by a high level of precision by offering a service of transforming a physical model into a parametric three-dimensional model.

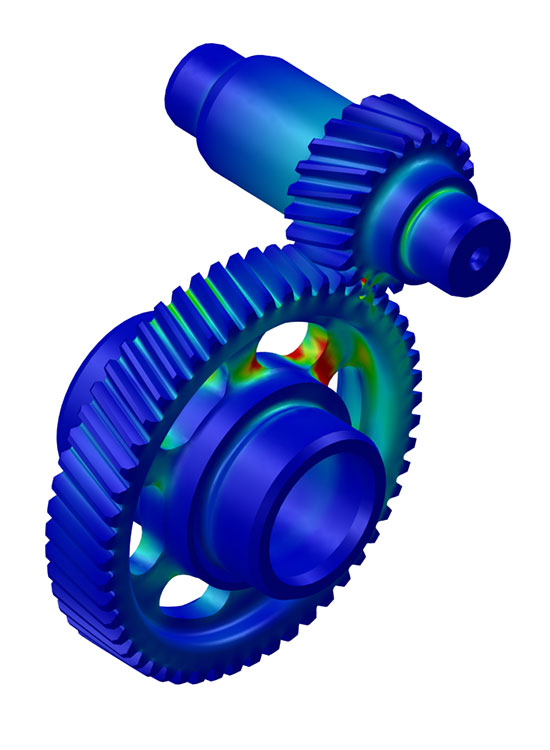

Thanks to finite element analysis we can evaluate the performance of a product while it is still in the design phase. Being able to analyze in advance the stability, resistance and deformations to which a solution may be subject enables a more informed and safe passage to the production phase, whilst avoiding any over-sizing or design flaws.

The industrialisation process results from the synergy of mechanical design and surface modeling, with the purpose of obtaining a final industrial design. In this phase the functional and ergonomic aspects that make up a given product are studied and designed, while the aesthetic appearance is established through the development of a final 3D model of all the components.

Through knowledge of standards and regulations, with detailed engineering we can obtain 2D project constructs according to the various quality standards required.

File storage can take place directly in the customer's PDM through secure VPN communication computer channels.

We provide companies with qualified technical support, accompanying them in every step of the design process. From cost analysis to supplier selection, we build a journey with the client, aiming to meet their requirements in the shortest possible time. We leverage all our skills to optimize the production process, eliminating potential errors and simplifying the scale-up of the finished product.