Round Stove Development

AMG S.p.A.

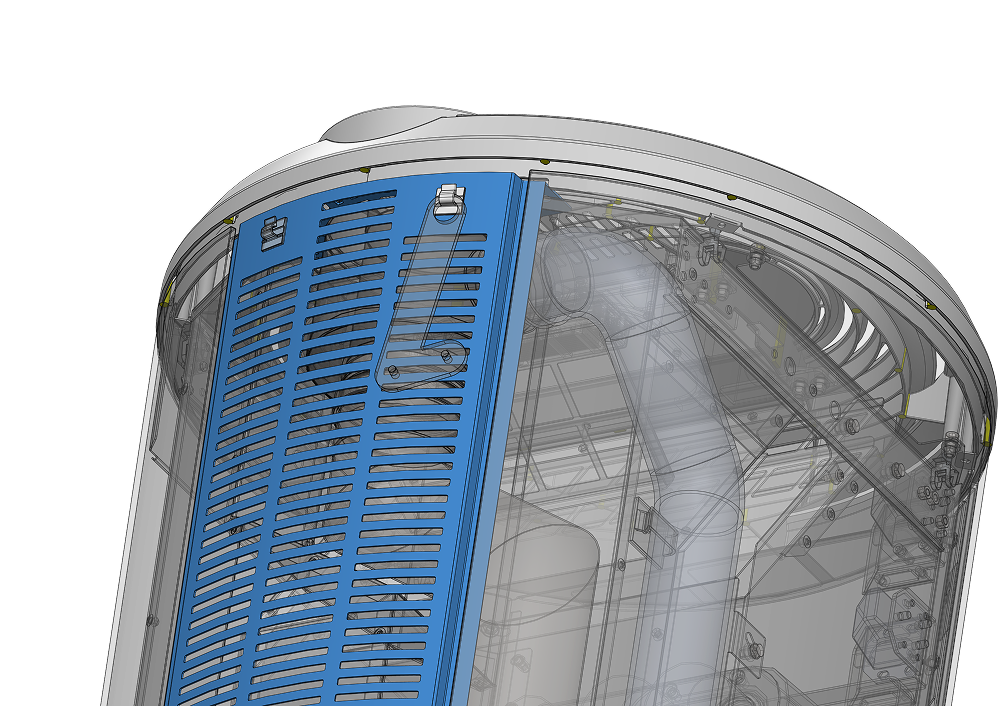

During the development process of the new AMG round stove, a complete technical overhaul was carried out with the goal of improving performance, build quality, and functional consistency. The entire project focused on optimizing every component—from the top to the base and the rear—by introducing innovative engineering solutions and advanced manufacturing technologies. The result is a product that combines efficiency, safety, and perceived quality.

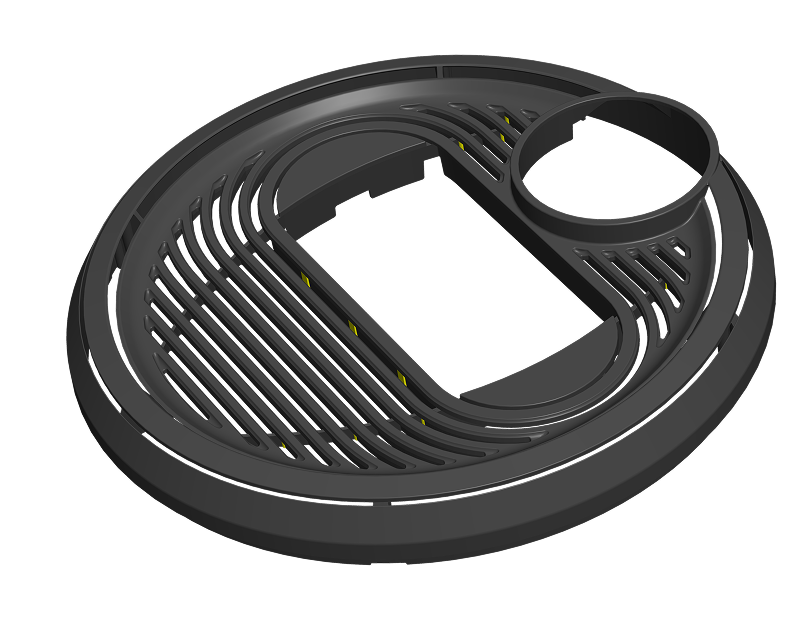

The upper section of the stove was designed to prevent accidental pellet drops into the machine body and to optimize the distribution of hot air. The top’s geometry ensures the correct channelling of airflow, enhancing thermal efficiency and contributing to the system’s safety. This solution integrates functionality, reliability, and formal cleanliness.

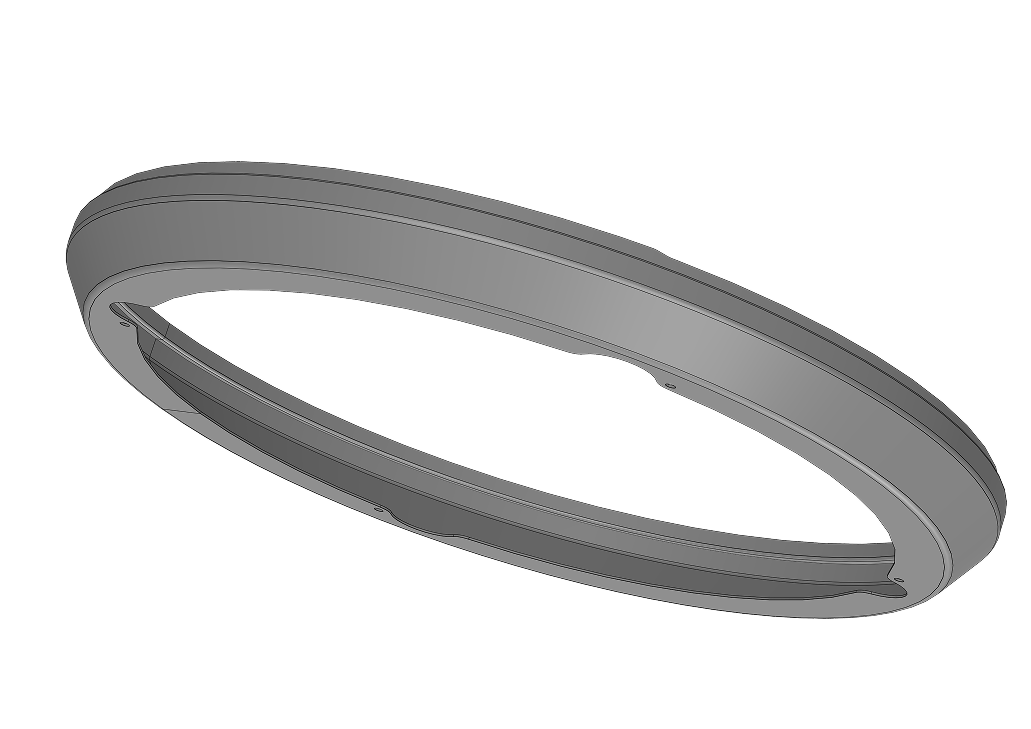

The base was manufactured using metal spinning technology, an innovative technique in the heating sector. This process allows for a high-quality aesthetic finish and an especially robust structure, offering advantages in both mechanical strength and geometric precision. The result is a functional component with a refined visual appeal.

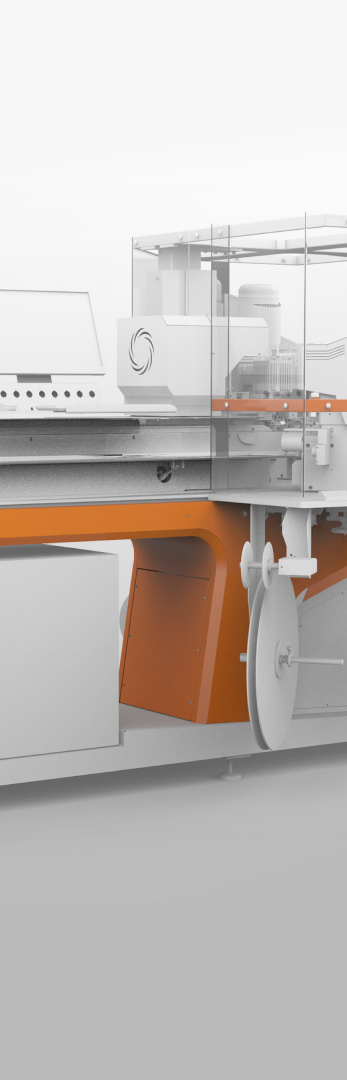

For the first time, the stove features a fully round shape, including the rear section. This required a complete redesign of the internal configuration and technical constraints, in order to maintain accessibility and functionality despite the formal continuity. The curved back ensures a coherent appearance from every angle, making the product ideal for central or exposed installations.